Page 11 of 20

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 4:42 pm

by 3X00-Modified

I posted about it and told Bret when I was doing Roberts that you have to grind the jack shaft from the Jbody to clear the block. He as typical disagreed with me even when I posted pictures of the interference.

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 7:17 pm

by MY91GT(Z)

Nice progress glad.to see someone still showing progress here on the forum too. Keep up the good.work

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 8:42 pm

by 3X00-Modified

Hey now, wait till fall... I'll have dueling projects going on in my garage... Talk about a wallet emptier...

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 8:58 pm

by MY91GT(Z)

Been waiting for u to start ur nitrous set-up....

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 9:28 pm

by 90GTZHO

Am i moving too fast or something? Lol! I need her back on the road like yesterday so im trying to get it all done and taken care of. Ive done a 5spd swap before, but i did not need to do any welding, just the holes for the clutch pedal and master. Im hoping to hang the motor and trans tonight...we will see...

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Sat Oct 18, 2014 9:53 pm

by MY91GT(Z)

Get-r-done Geoff

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Tue Oct 21, 2014 12:46 pm

by 90GTZHO

Lol! I have the drivetrain back in the car now. Dont have alot of pics but i will make a full update here later today.

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Tue Oct 21, 2014 7:28 pm

by themixer

pics or it didn't happen

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Tue Oct 21, 2014 7:57 pm

by Money pit Beretta

themixer wrote:pics or it didn't happen

I needed that one. Have not heard that one in years.

Re: Project Second Chance - Makin Tracks PG10!!

Posted: Tue Oct 21, 2014 10:00 pm

by 90GTZHO

Soooooooooo....update time.

This past Sunday i made a huge effort to get things going on my car. I had to do a thermostat and a water pump on my fiance's car so i lost about 3 hours doing that, but all's well.

Anyways, i will spare the details of how i lost another hour over something stupidly freaked me out. Long story short, the drive train is back in and hanging on its own. Was kinda funny, without the frame rails installed and it sitting there by the two upper mounts, you could swing the motor front to back with your pinky finger lol.

Again, sorry for the blurry pics, for some reason the florescent lights mess with the camera on my phone.

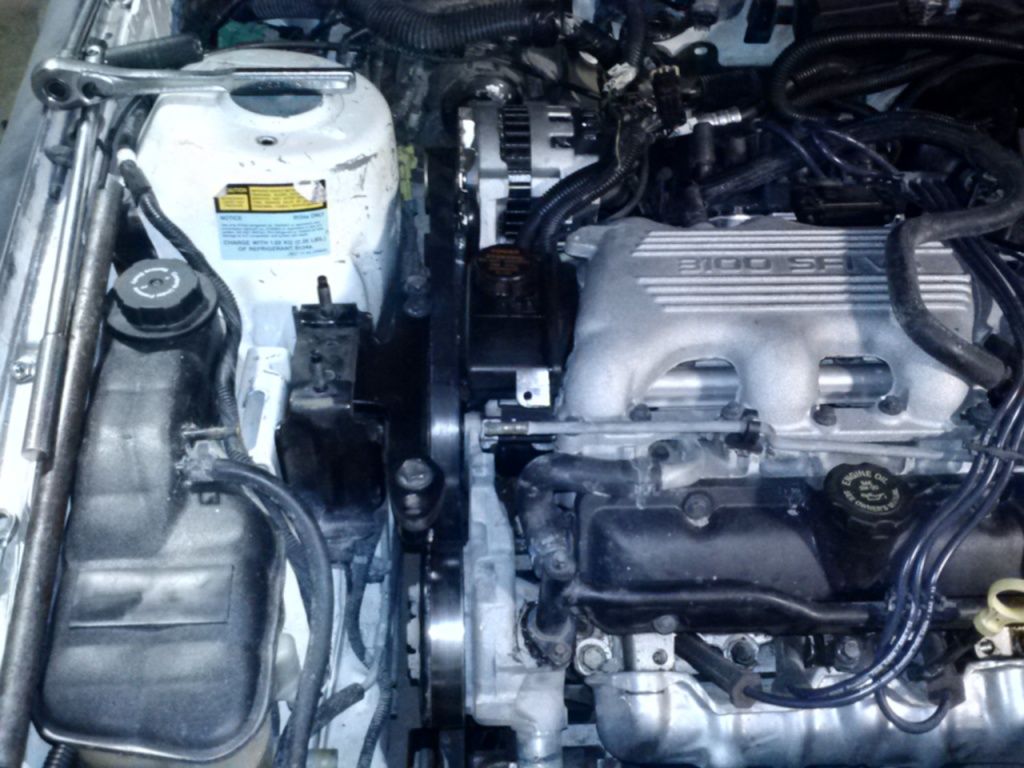

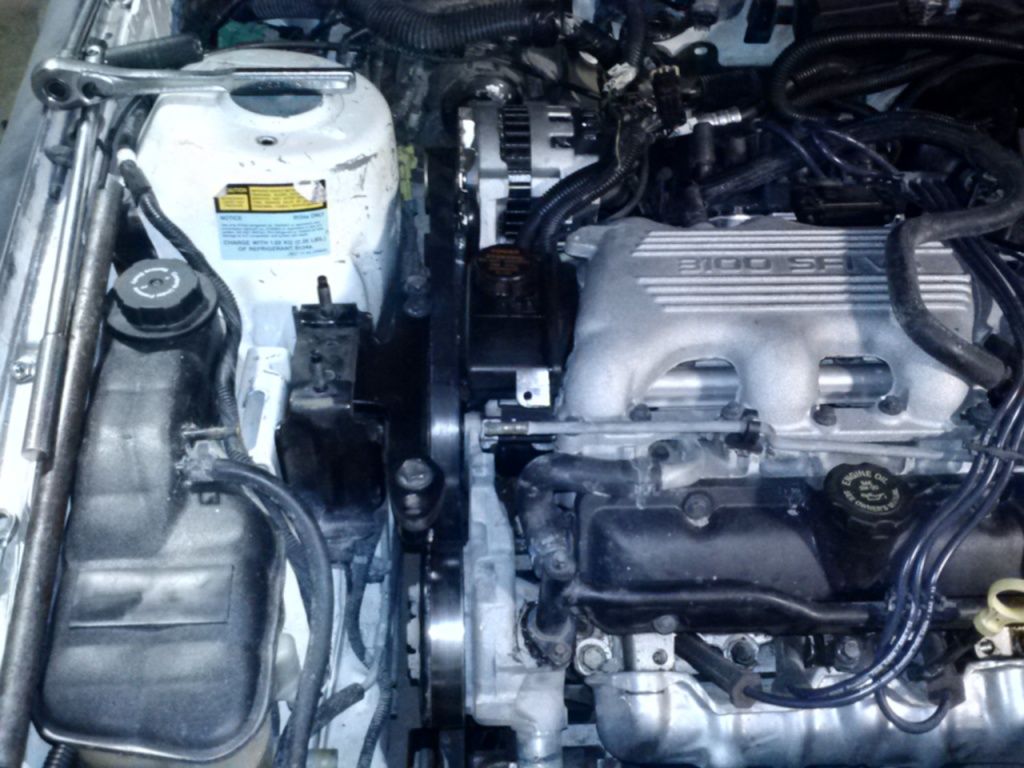

Just after hanging the setup

Then i got the accessories reattached and belted and hooked the wiring back up.

I ran out of time on that night/morning, so i went home and got some rest. Was back at it Monday afternoon/early evening. Got the passenger frame rail installed, passenger dog bone attached and checked the motor for firmness. Decided that, indeed, i should have the 88-91 L- and 88-94 J-body driver side lower dog bone hooked up. So since i didnt want to buy another frame rail, i built a mount for that dog bone. By the time i was out of time and had to go home, i had the mount made, and painted, but the frame not reinstalled. So next time im out there, i have to install it still. Its a little over kill on the design, but i like things strong.

NO pics of it painted, but i will get those next time im there. More on the way, should be driving it by net weekend....i hope. If i stop finding things i want to replace lol.

Re: Project Second Chance - Gettin There PG11!!

Posted: Wed Oct 22, 2014 7:47 am

by Money pit Beretta

Those are some thick welds, what are you using again? Kind of shocked that you don't have burn through on the stock frames.

Re: Project Second Chance - Gettin There PG11!!

Posted: Wed Oct 22, 2014 7:58 am

by 3X00-Modified

Slow down the wire speed and drop the heat a little... Dialing in the welder is the biggest talent that many don't have... After that it's quite easy to lay a bead. You may also have too think of wire in the welder to work on material like that. I've found the best size is .023 wire... You can weld thin stuff easily and not require a lot of heat but at the same time you can weld 1/8th" plate steel with it too.

Re: Project Second Chance - Gettin There PG11!!

Posted: Wed Oct 22, 2014 9:17 am

by heavywoody

I've been told to push the bead instead of pull it with thinner material too... I still need to try that since the stuff I normally weld isn't nearly as thin.

Re: Project Second Chance - Gettin There PG11!!

Posted: Wed Oct 22, 2014 9:45 am

by 90GTZHO

A coworker told me that if you are mig or tig welding, no matter what you are welding, you always push the welds rather than drag them, as pushing them leaves more gas around for the weld where dragging the weld will dissipate the gas faster. He was right. I dragged the welds on my frame mount for my trans swap and they didnt come out as well. I pushed the welds when i built my frames' dog bone mount and the welds look 4x nicer and laid alot more flat and smooth.

Re: Project Second Chance - Gettin There PG11!!

Posted: Wed Oct 22, 2014 9:54 am

by 90GTZHO

In all honesty, they dont look as thick in the pics as they do in person. I just have shitty resolution on my phone. Some of the welds are built up welds too. There was one or two spots where i had to fill in a gap. I had the power turned down all the way when i started and it was barely dropping a bead. This was the second of 4 heat ranges on the welder i was using. Its just a mig welder and not the best innthe world, but the welds have good penetration and im confident they will hold fine over the years. I may go back and do a little grinding, but it not gonna be a show car. As long as it holds, im happy